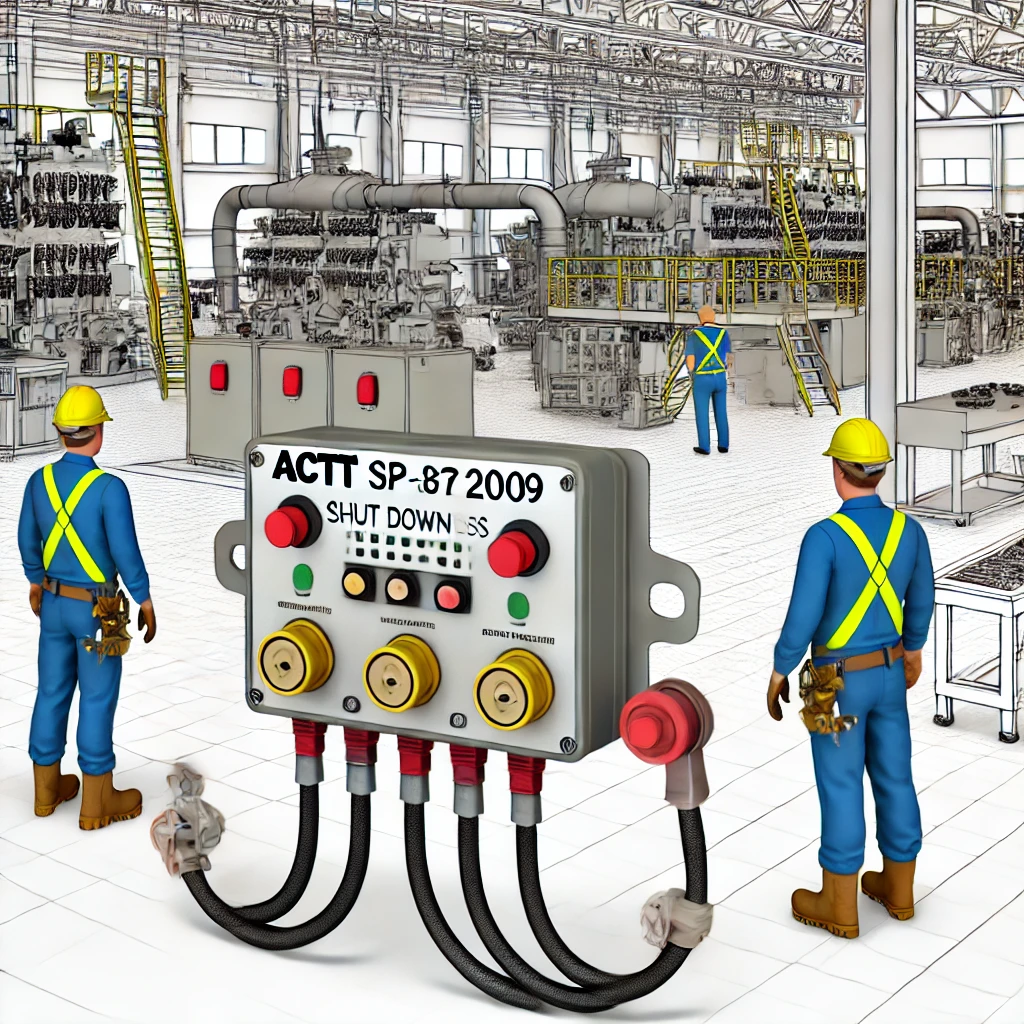

In the complex and hazard-prone world of industrial machinery, ensuring operational safety while maintaining efficiency is paramount. The ACTT Service Program SP 3-872-009 Shut Down Harness emerges as a critical solution, designed to swiftly halt operations of machinery at the first sign of trouble. This harness is not just a safety apparatus; it’s a vital part of a system that preserves machine health, protects human operators, and minimizes costly downtime.

What is the ACTT SP 3-872-009 Shut Down Harness?

The ACTT SP 3-872-009 Shut Down Harness, a specialized device, integrates into industrial systems to provide rapid power shutdowns in emergencies. Whether due to mechanical failure, process error, or operator misjudgment, this harness can cut power, stopping machinery instantly and safely.

ACTT Service Program SP 3-872-009 Shut Down Harness Key Features

- Immediate Response: Initially, designers have made the harness to trigger an immediate halt to all connected machinery, thereby reducing the risk of injury and equipment damage.

- Integration Ease: Furthermore, it seamlessly integrates with existing safety protocols and machinery setups, thus ensuring minimal disruption to operations.

- Customization: Additionally, operators can customize the harness to various machinery types and sizes depending on the operational requirements, consequently making it versatile across different industrial applications.

- Durability: Moreover, constructed from high-quality materials, it withstands harsh industrial environments and repetitive use without degrading in performance.

ACTT Service Program SP 3-872-009 Shut Down Harness Applications in Industries

Indeed, the versatility of the ACTT SP 3-872-009 Shut Down Harness allows multiple sectors to apply it:

- Manufacturing: For assembly lines where immediate stoppage is crucial during a fault.

- Energy Production: In power plants, where the cost of equipment failure can be astronomical.

- Chemical Processing: It provides an essential safety measure in the handling of potentially dangerous substances.

Why Choose the ACTT SP 3-872-009 Shut Down Harness?

Enhancing Safety Protocols

Safety is the paramount concern in any industrial setting. The ACTT harness enhances existing safety measures by providing an independent and reliable shutdown method that can prevent potential disasters before they escalate.

Reducing Operational Downtime

By stopping machines promptly in an emergency, the harness effectively prevents extended damage which can lead to prolonged repairs and downtime. Consequently, quick interventions maintain operational continuity and efficiency.

Compliance with Safety Standards

Significantly, designers have made the ACTT harness to meet rigorous industry safety standards, thereby ensuring compliance and peace of mind for business operators and safety inspectors alike.

ACTT Service Program SP 3-872-009 Shut Down Harness Advanced Monitoring Capabilities

Seamless System Integration for Enhanced Monitoring

A standout feature of the ACTT SP 3-872-009 Shut Down Harness is its advanced monitoring capabilities, which allow for real-time diagnostics and status updates of machinery operations. This harness isn’t just a reactive safety measure—it actively monitors the performance parameters of connected machines, providing alerts before conditions reach critical levels. By preemptively identifying potential issues, operators can address problems before they necessitate an emergency shutdown, thus maintaining smoother operations and better overall system health.

ACTT Service Program SP 3-872-009 Shut Down Harness Cost-Effectiveness and Long-Term Benefits

Maximizing ROI with Durable Safety Solutions

Investing in the ACTT SP 3-872-009 Shut Down Harness translates into significant cost savings over time. The reduction in emergency repairs, machinery downtime, and extended lifespan of equipment due to preventative maintenance offsets the initial setup cost. Additionally, the decrease in workplace accidents reduces potential legal and medical expenses, not to mention the invaluable benefit of maintaining a safe working environment for employees. For businesses, this means not just meeting but exceeding safety standards, which can enhance their market reputation and lead to more business opportunities.

User-Friendly Design and Operation

Simplifying Safety with User-Centric Designs

Ease of use is a critical design element of the ACTT SP 3-872-009 Shut Down Harness. Engineers have made the harness user-friendly, requiring minimal training for operators to understand its functionality. This design philosophy ensures that all personnel, regardless of their technical skill level, can effectively manage and utilize the harness. Visual indicators and straightforward control mechanisms allow for quick actions in emergency situations, further enhancing the safety measures within any industrial setup.

Future-Proofing with Technological Advancements

Staying Ahead: Adapting to Future Industrial Needs

The ACTT SP 3-872-009 Shut Down Harness is built with future technological advancements in mind. As industries evolve and new technologies emerge, operators can update or modify the harness to accommodate new machinery and safety standards. This adaptability makes it a sustainable choice for businesses looking to future-proof their operations against evolving industrial landscapes. By choosing the ACTT harness, companies not only address current safety needs but also prepare for future challenges and innovations.

Conclusion

The ACTT Service Program SP 3-872-009 Shut Down is more than just a piece of equipment; it is a vital investment in the safety and efficiency of industrial operations. By integrating this harness into their safety protocols, businesses can protect their workforce, prevent significant financial losses due to equipment damage, and ensure compliance with international safety standards. Finally, as industries continue to evolve and expand, the reliance on such advanced safety mechanisms will only increase, making the ACTT harness an indispensable tool in the industrial landscape.